-

Our Products

- Laser Welding Machine

- Laser Marking Machine

- Laser Marker

- Jewelry Laser HallMarking Machine

- Portable Laser Marking Machine

- Industrial Laser Marking Machine

- Portable Laser Fiber Marking Machine

- UV Laser Marking Machine

- Co2 Galvo Laser Marking Machine

- Co2 Laser Marking Machine

- Fiber Laser Cutting Machine

- 3D Laser Marking Machine

- Bearing Laser Marking Machine

- Colour Laser Marking Machine

- Desktop Fiber Laser Marking Machine

- Fiber Laser Marking Machine

- Fly Marking Machine

- Galvo Laser Marking Machine

- Handheld Fiber Laser Marking Machine

- Handheld Laser Marking Machine

- Laser Marking Machine

- Metal Laser Marking Machine

- Portable Handheld Laser Marking Machine

- Laser Engraving Machines

- Laser Marking and Engraving Machine

- Laser Rust Cleaning Machine

- Laser Marking And Engraving Services

- Laser Hallmarking Machine

- SPM Machine

- Laser Optics

- Yag Optics

- Home Page

- Company Profile

- Contact Us

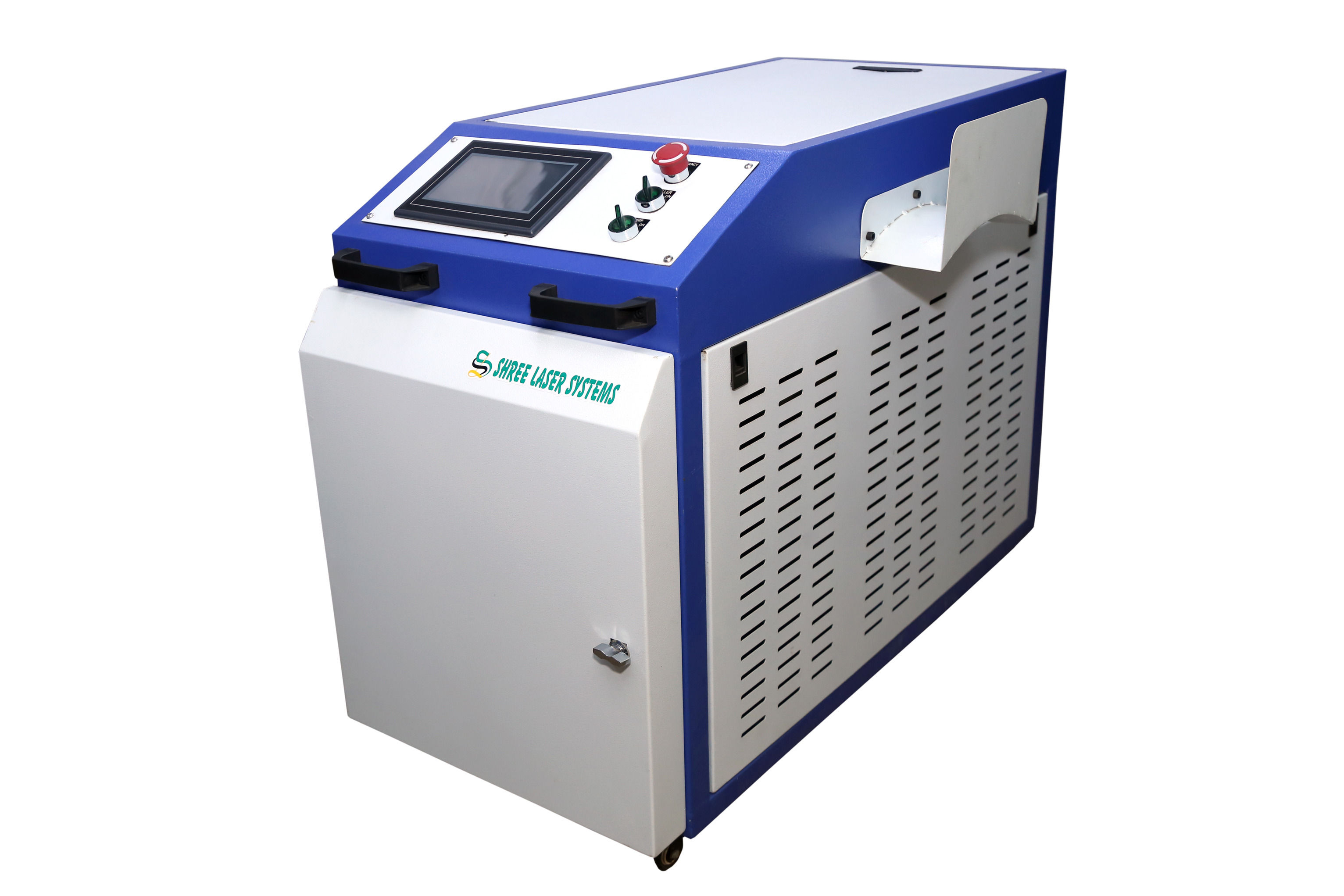

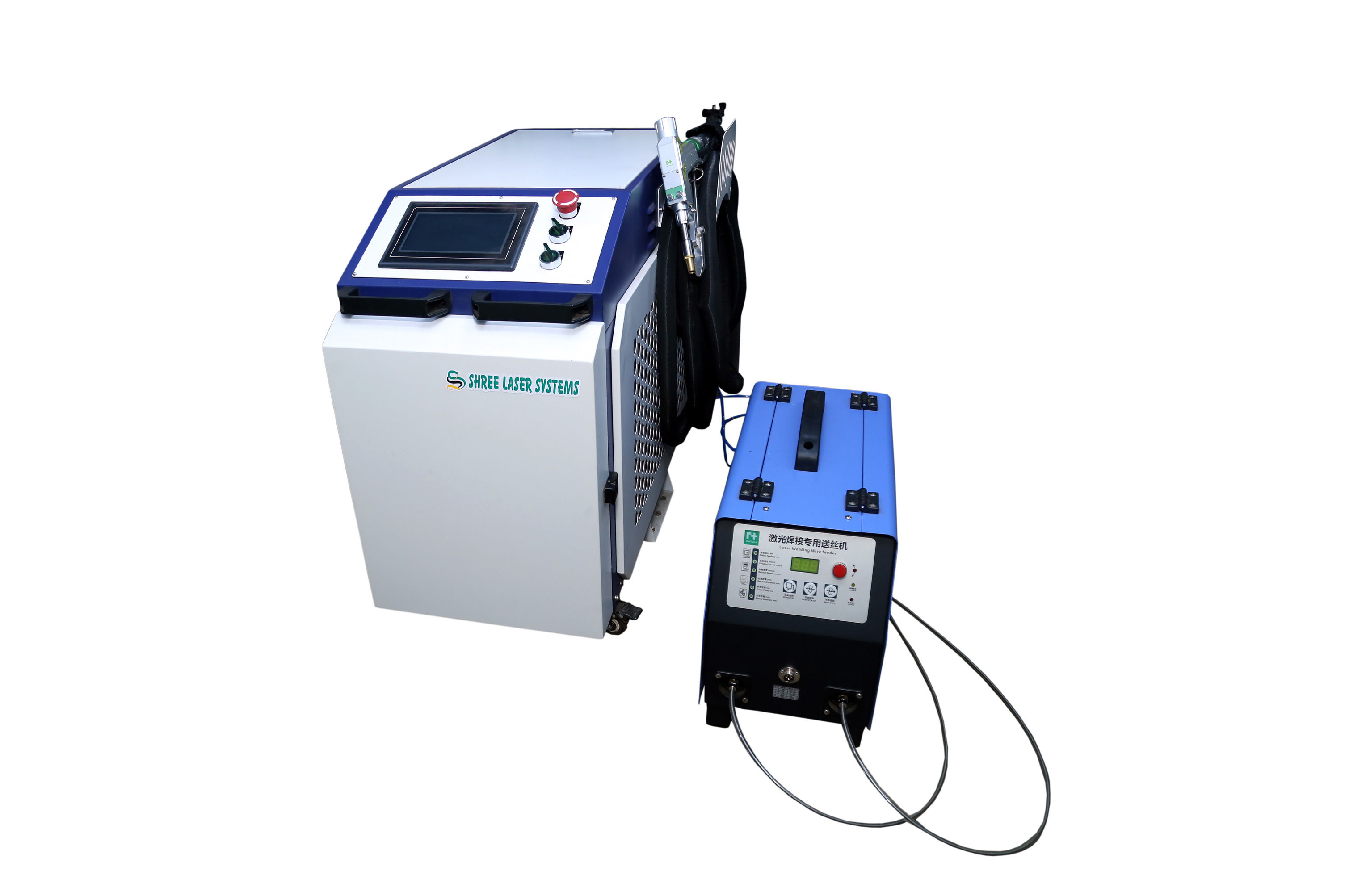

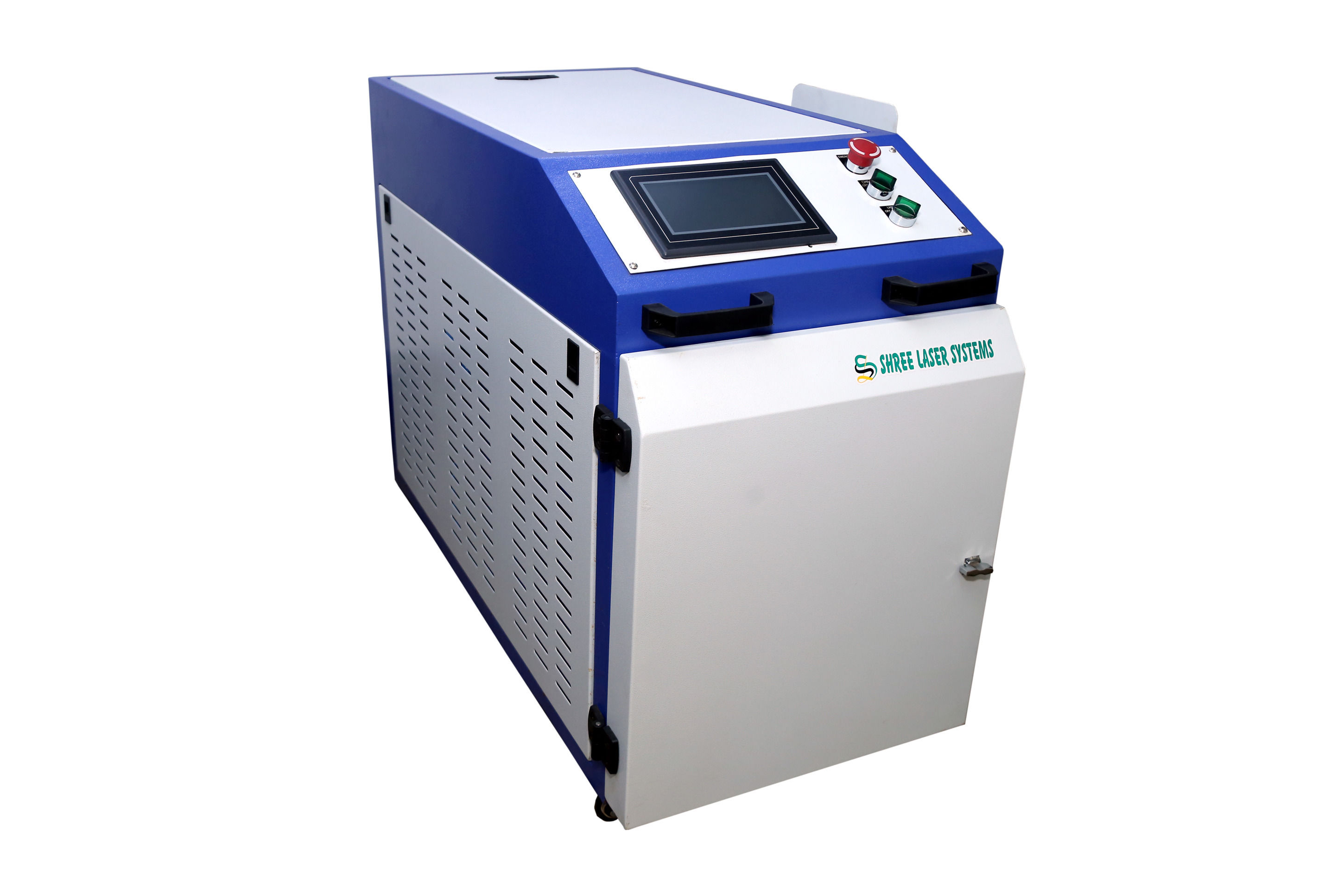

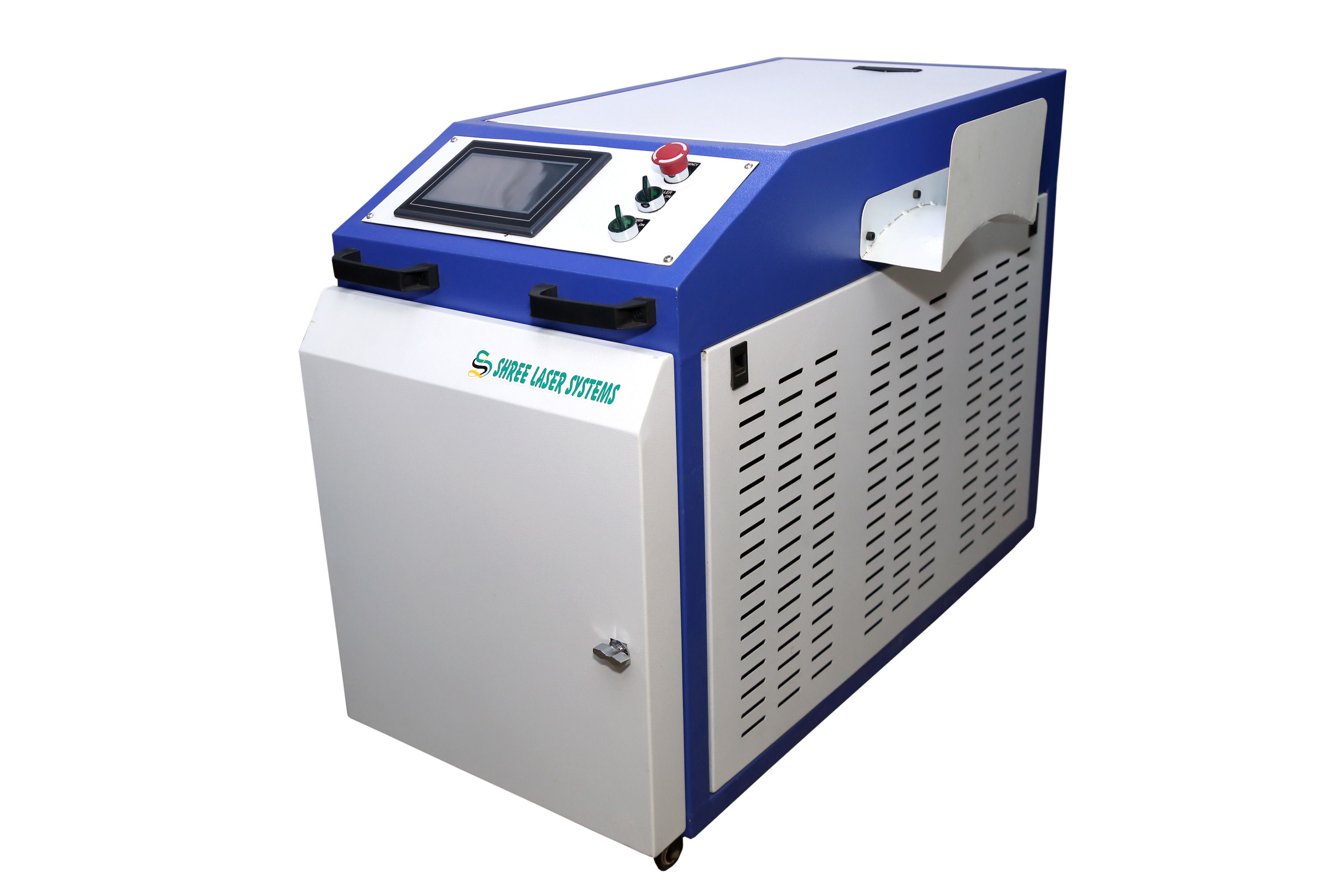

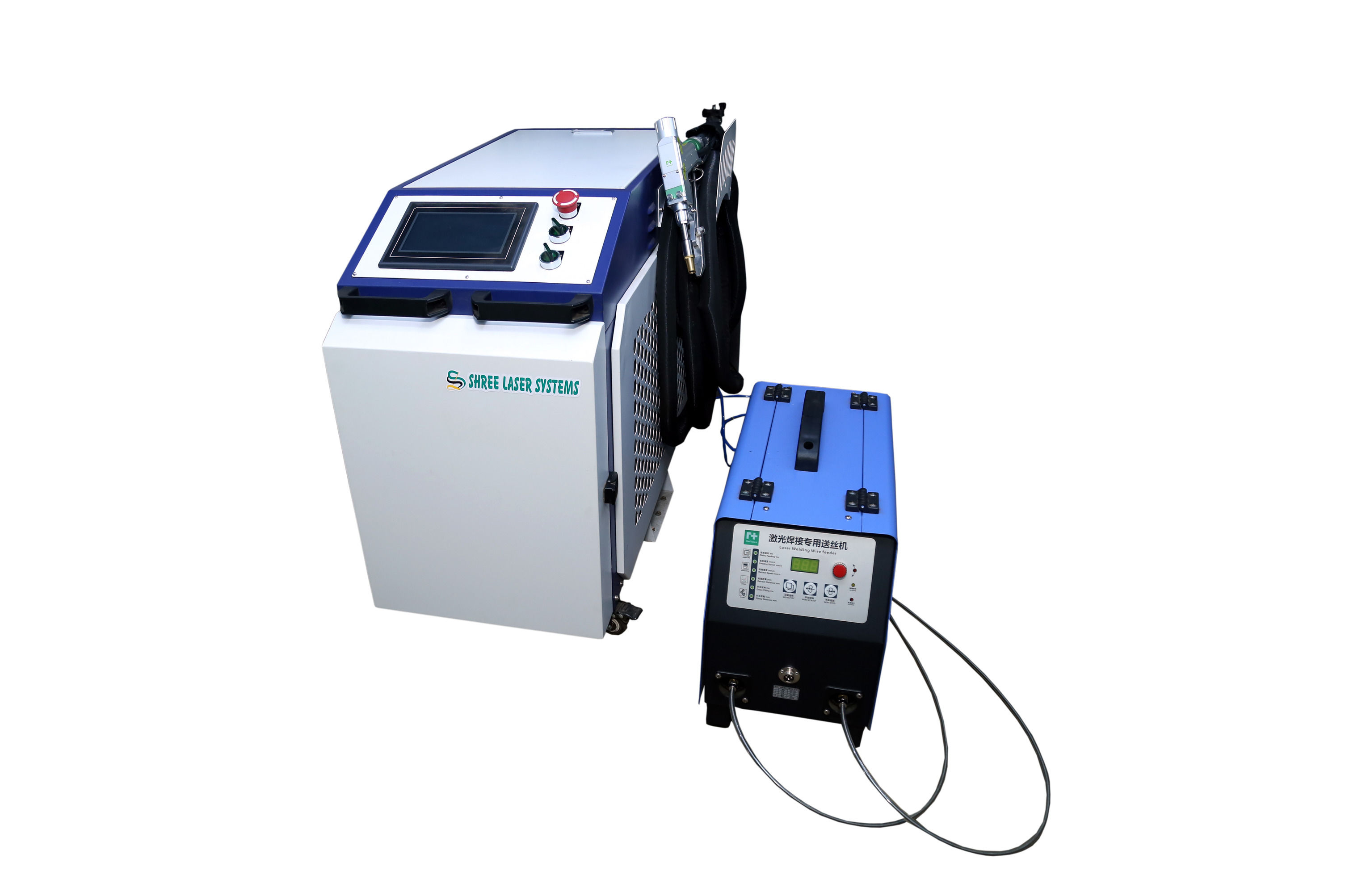

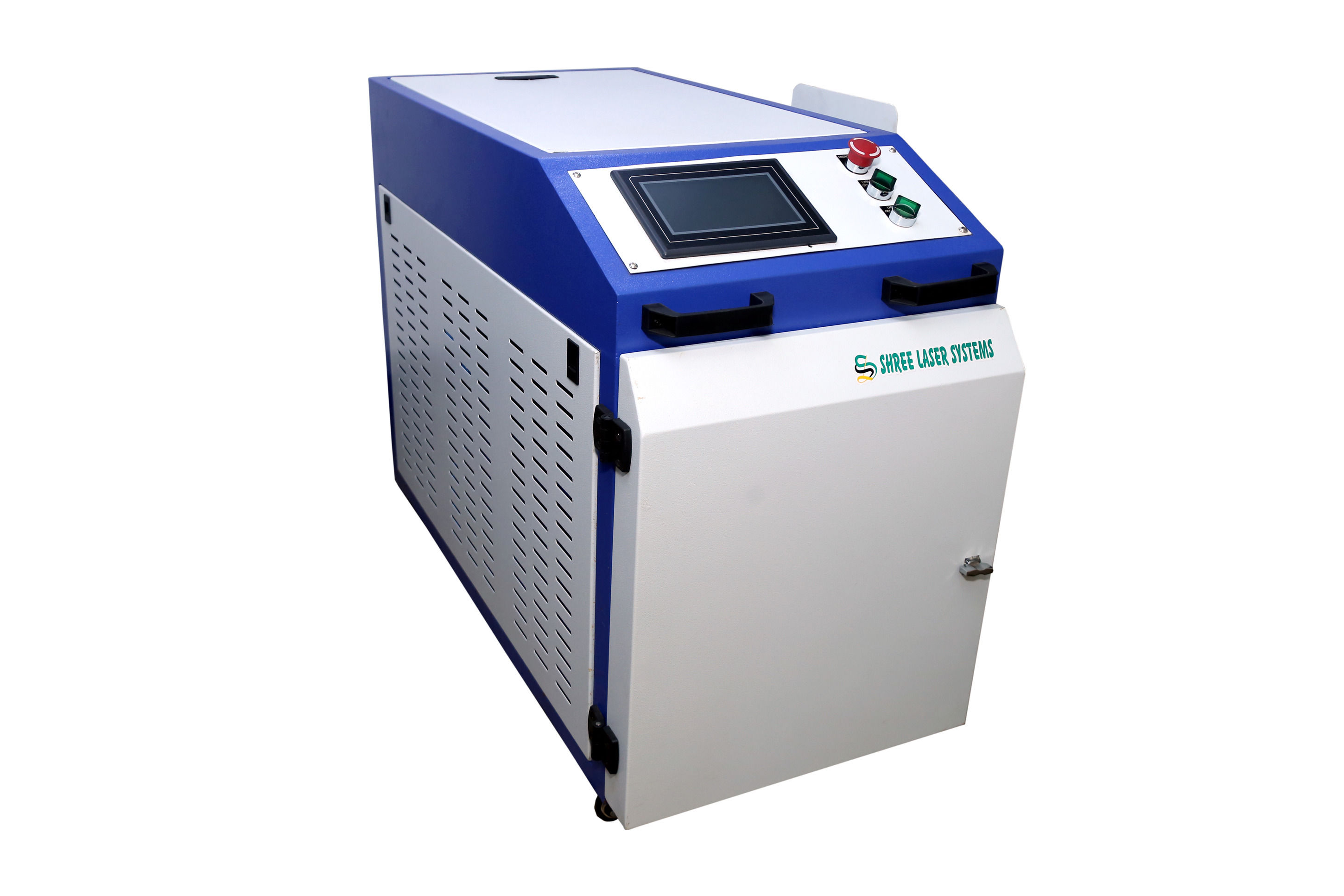

High-speed laser welding Machine

550000.00 INR/Number

Product Details:

- Weight 120 Kilograms (kg)

- Voltage 230 Volt (v)

- Condition New

- Output Current 230 Volt (v)

- Welding Area 0.5 mm to 8 mm

- Cooling Method Water cooled

- Function Welding

- Click to View more

X

High-speed laser welding Machine Price And Quantity

- 1 Number

- 550000.00 INR/Number

High-speed laser welding Machine Product Specifications

- 1000 x 500 x 800 Centimeter (cm)

- 1064

- Welding

- 230 Volt (v)

- 230 Volt (v)

- 120 Kilograms (kg)

- New

- 0.5 mm to 8 mm

- Water cooled

- 1000 W to 3000 W Watt (w)

- 230

- 0.8 mm to 1.6 mm

- Laser Welding Machine

High-speed laser welding Machine Trade Information

- 15 Number Per Month

- 10 Days

- Yes

- Free samples are available

- All India South India Central India West India North India East India Gujarat Karnataka Kerala Lakshadweep Mizoram Meghalaya Manipur Andhra Pradesh Bihar Chandigarh Daman and Diu Goa Jharkhand Odisha Punjab Assam Delhi Dadra and Nagar Haveli Andaman and Nicobar Islands Arunachal Pradesh Chhattisgarh Haryana Himachal Pradesh Jammu and Kashmir Madhya Pradesh Maharashtra Nagaland Rajasthan Sikkim Tamil Nadu Telangana Tripura Pondicherry Uttar Pradesh Uttarakhand West Bengal

Product Description

High-speed laser welding is an advanced manufacturing process that uses a concentrated laser beam to join materials, typically metals, at extremely high speeds. The laser produces intense heat that rapidly melts the material, allowing it to fuse together as it cools, creating a strong and precise weld. This method is popular in industries such as automotive, aerospace, electronics, and medical devices due to its speed, accuracy, and ability to work with a variety of materials, including stainless steel, aluminum, and titanium.

The high-speed laser welding process is often paired with automation, such as robotic arms or CNC machines, to ensure consistency and precision in large-scale production. It also allows for deep penetration welding, which results in strong welds in thin and thick materials alike. Moreover, this technique produces minimal distortion, as the heat-affected zone is small compared to traditional welding methods.

Key Advantages:

- Fast processing speeds, improving productivity

- Precise and clean welds with minimal post-processing

- Minimal heat distortion and smaller heat-affected zones

- Compatibility with a wide range of materials

- Reduced wear and tear compared to mechanical methods

FAQs on High-Speed Laser Welding

Q1: What types of materials can be welded with high-speed laser welding?A1: High-speed laser welding can be used on a wide range of metals, including stainless steel, carbon steel, aluminum, copper, brass, titanium, and alloys. It can also be used to weld dissimilar materials, though special considerations may be needed for different material properties.

Q2: What industries commonly use high-speed laser welding?A2: Industries such as automotive, aerospace, electronics, medical device manufacturing, and precision engineering frequently use high-speed laser welding due to its precision, speed, and ability to produce high-quality welds. It's particularly valuable for industries that require high throughput and tight tolerances.

Q3: How does high-speed laser welding compare to traditional welding methods?A3: Compared to traditional methods like MIG or TIG welding, high-speed laser welding is much faster, more precise, and produces less heat distortion. It also requires less post-processing and is suitable for automation, making it ideal for high-volume production.

Q4: What are the limitations of high-speed laser welding?A4: Some limitations include the high initial investment in laser welding equipment, potential challenges in welding highly reflective materials like copper, and the need for precise setup to avoid defects like porosity or incomplete fusion.

Q5: Can high-speed laser welding be used for dissimilar material welding?A5: Yes, it is possible to weld dissimilar materials using laser welding, but it requires special techniques to accommodate the different melting points, thermal conductivities, and expansion rates of the materials.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Email

Send Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese